Equipment endowment keeps Watson College’s technology up to date

Over the past two decades, more and more everyday products are made through automated manufacturing. Control units manage the servo motors, sensors, solenoids and robotics needed to perform repetitive tasks in an efficient way to ensure smooth production.

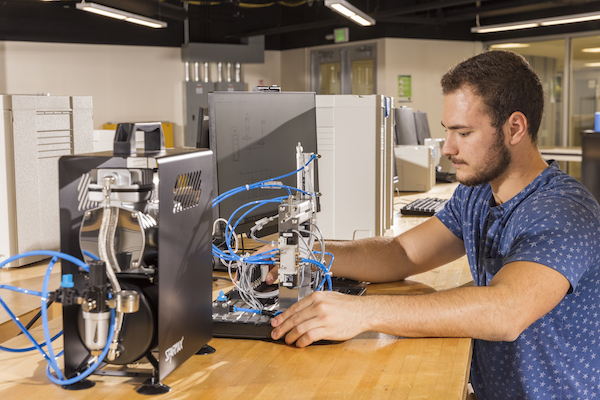

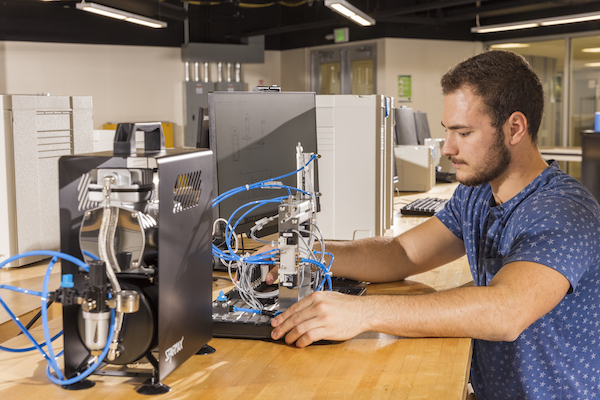

At Watson College, undergraduates studying industrial and systems engineering learn to manage the right mix of people, robots, industrial equipment and data to make the whole process work. Computer simulations are helpful, but when they need hands-on experience, the Advanced Manufacturing Lab in the Engineering Building is the place to be.

The lab includes five Festo training systems, which feature scaled-down versions of the same mechatronics used in manufacturing. They were purchased through Watson’s equipment endowment and installed in fall 2020. Each system has a conveyor, handling and stacking magazine to simulate an automated production line, and they can be used in combination or as stand-alone stations.

Assistant Professors Yingge Zhou and Fuda Ning from the Department of Systems Science and Industrial Engineering use the modular learning systems and the accompanying software for their Industrial Automation and Control courses.

“Students write the code and organize the components on the computer to figure out a solution and program the mechatronics to move correctly,” Zhou says. “Then they try it in real time on the testing device, learning how the programmable logic controller works, how the pneumatic components work, how the actuator and sensors work, and how these can achieve real-world manufacturing functions together.”

“I believe the SSIE Department at Watson has one of the first industrial and systems engineering programs in the nation to offer such a hands-on lab as part of its undergraduate curriculum to provide students an opportunity for real-world automation problem-solving,” Ning says.

Financial gifts earmarked for tech upgrades fund the equipment endowment.

“It enables students to conduct research using the most current and sophisticated lab equipment,” says donor Ken Goldblatt ’87. “This experience prepares them for their careers in industry.”

Goldblatt, a board member for the Binghamton University Foundation, graduated from Binghamton with a computer science degree in 1987 and earned his MBA in finance from New York University’s Stern School in 1992. Today, he is the CIO and portfolio manager at S Squared Technology, a hedge fund that invests in small- and mid-sized technology companies.

In 2017, he started the Goldblatt Challenge to encourage faculty and staff to become more involved in Watson College’s success through giving. The final year of the four-year initiative had 44.8% participation, with Goldblatt contributing matching funds.

“Having cutting-edge equipment is just one way that Binghamton can compete with other universities for top undergraduate and graduate students, as well as recruit and retain professors,” he says.