WELCOME TO THE RAZAVI RESEARCH GROUP

Mechanics of Soft/Bio Materials Lab

Welcome to the research group website of Mir Jalil Razavi, an assistant professor of mechanical engineering for the Thomas J. Watson College of Engineering and Applied Science at Binghamton University (State University of New York).

In our group, we try to understand the mechanical properties and behavior of materials in both engineering and biology using theoretical analysis, computational modeling and experimental investigation.

Our current research focuses on the study of physics and characterization of soft materials, especially growth and remodeling of soft biological tissues (such as the brain and skin) to understand the fundamental principles of growth, morphological instability and post-instability pattern selection of living tissues.

Research

The following research topics are some of our ongoing projects.

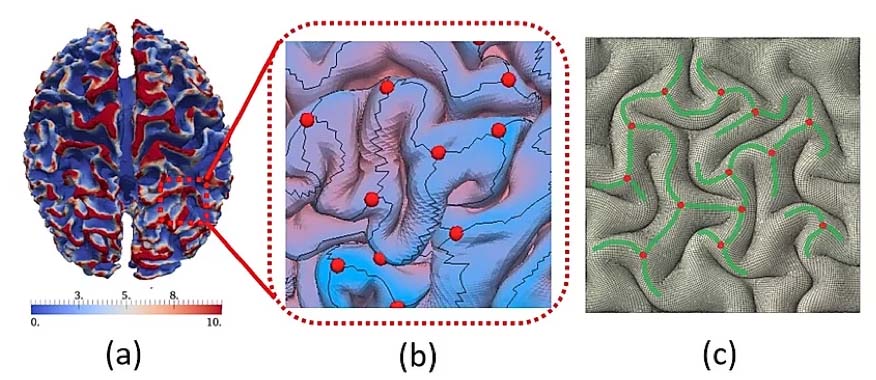

(a) 3-hinges in a brain has higher concentration of axon fibers. (b) Red dots show identified 3-hinges in a small part of the real brain image. (c) Non-linear finite element model mimics formation of 3-hinges in a growing brain.

Mechanics of the growth and folding of brain

The mechanical behavior of soft materials is strongly nonlinear from both physical (constitutive equations) and geometrical (large deformations) standpoints, which makes its study challenging.

The brain is a good example of soft matter with complex structure and function. We are doing research in the theoretical and computational modeling of growth, instability and folding of a growing brain. Brain mechanics is a fully interdisciplinary research area that integrates multiple scientific, engineering and computational disciplines.

The goal of this research is developing innovative computational and technological approaches to study the links between brain growth and post-instability morphogenesis. This effort will lead to new insights into topics such as fundamental mechanisms for development and organization of cerebral cortex.

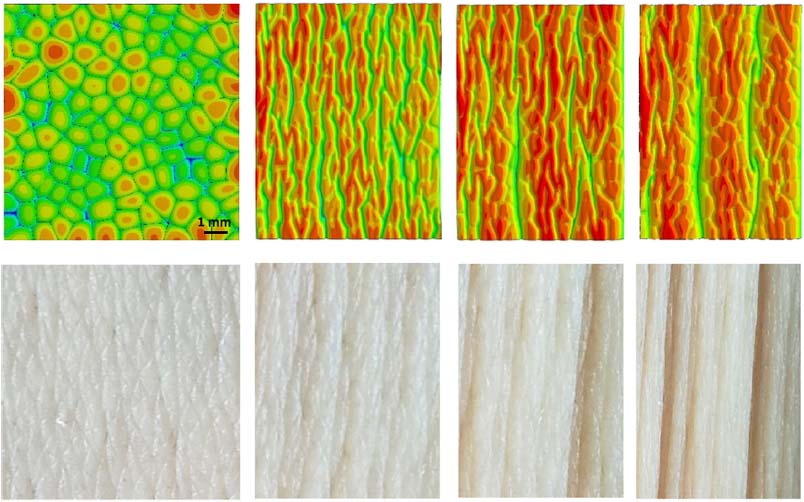

Mechanics of wrinkling and aging of skin

A major concern associated with skin, the largest organ of our bodies, is how to prevent it from wrinkling and aging. Understanding the mechanics of skin wrinkling can provide useful insight into skin aging prevention. However, despite decades of research, the underlying mechanism of skin wrinkling and aging remains poorly understood. We explore the effect of geometrical and mechanical properties of skin on its wrinkling through an integrated theoretical and computational analysis.

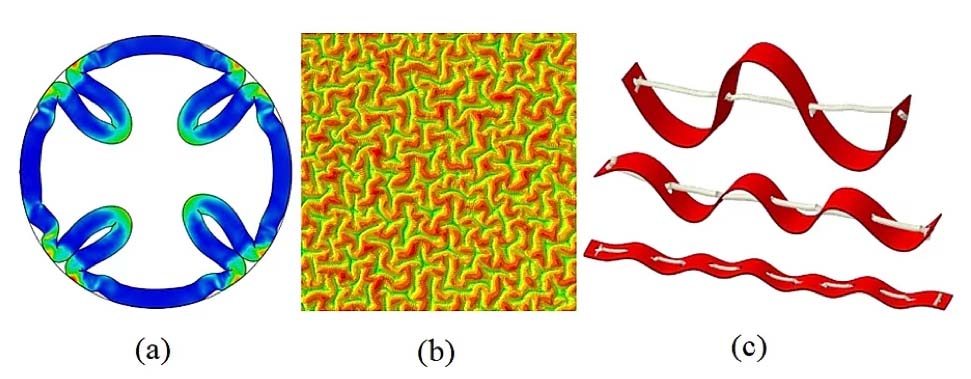

(a) Growth of a soft tube in a confined boundary. (b) Surface nano-creasing of a polymeric brush. (c) Creating 3D structures by thermoresponsive fibers.

Mechanics of instability and

morphogenesis of soft materials/tissues

Growth, morphological instabilities and post-instability surface patterns of soft materials such as elastomers, polymeric gels and biological soft tissues are a hot topic to a number of research fields, including functional material, soft lithography, flexible electronics and biomedical engineering.

Morphological surface instability of soft materials with a wide-ranging application has attracted great interest among academics over the past decade. Growth and creasing of solid tumors, wrinkling of mucosa in the esophagus, rippling of leaves, buckling of artery, surface wrinkling and creasing of a swelling hydrogel, and wrinkling of the gut all are examples of growth and remodeling of soft tissues which undergo large deformation and acquire various morphological instabilities in response to self or environmental stimuli. Therefore, we try by analytical, computational and experimental effort to explore characteristics of surface patterns as well as understanding the underlying physical mechanisms in different types of materials and tissues.

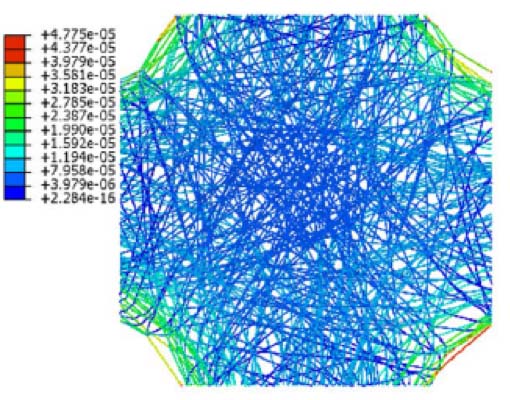

A mechanical model for the electrospun fibrous mat under biaxial tension with bonding between intersecting fibers.

Mechanics of electrospun fibrous mats

Electrospun fibrous mats, characterized by their large surface-to-volume ratios, have unique and beneficial properties for various applications. The micro- or nanoscale architectures of these structures affects the mechanical properties of the material.

The lack of knowledge for predicting the mechanical behavior of electrospun fibrous mats may prevent applications utilizing these mats from reaching their full potential. In this project, we try by multiscale modeling techniques to link the behavior of the bulk material to the microstructure architecture.

Group members

Principal investigator

Mir Jalil Razavi received his MS degree in solid mechanics from University of Tabriz in 2009 and his PhD degree in engineering (mechanics and materials) from the University of Georgia in 2018. He joined the mechanical engineering department at Binghamton University in fall 2018.

Razavi has published several peer-reviewed journal and conferences papers in the mechanics of soft materials.

Graduate Students

Poorya Chavoshnejad

PhD student

- MS: University of Tehran

- BS: Azad University (Central Tehran)

- Email: pchavos1@binghamton.edu

Ali Hoseinzadeh Foroughi

PhD Student

- MS: University of Tabriz

- BS: University of Tabriz

- Email: ahosein1@binghamton.edu

Akbar Solhtalab

PhD Student

- MS: Amirkabir University of Technology

- BS: University of Tabriz

- Email: asolhta1@binghamton.edu

Publications

- A. Solhtalab, A. H. Foroughi, L. Pierotich, M. J. Razavi*, “Stress Landscape of Folding Brain Serves as a Map for Axonal Pathfinding”, 2025, Nature Communications, 16, 1187. https://doi.org/10.1088/1478-3975/ad88e4

- H. Foroughi, C. Valeri, M. J. Razavi*, “A Review of Computational Optimization of Bone Scaffold Architecture”, 2024, Progress in Biomedical Engineering, 7, 012003. https://doi.org/10.1088/2516-1091/ad879a

- P. Chavoshnejad, G. Li, A. Solhtalab, D. Liu*, M. J. Razavi*, “A Theoretical Framework for Predicting the Heterogeneous Stiffness Map of Brain White Matter Tissue”, 2024, Physical Biology, 21, 066004. https://doi.org/10.1088/1478-3975/ad88e4

- A. H. Foroughi, D. Liu, M. J. Razavi*, “Simultaneous optimization of stiffness, permeability, and surface area in metallic bone scaffolds”, 2023, International Journal of Engineering Science, 193, 103961. https://doi.org/10.1016/j.ijengsci.2023.103961

-

P. Chavoshnejad, L. Vallejo, S. Zhang, Y. Guo, W. Dai, T. Zhang, M.J. Razavi. "Mechanical hierarchy in the formation and modulation of cortical folding patterns." Scientific Reports 13, no. 1 (2023): 13177. https://www.nature.com/articles/s41598-023-40086-9

-

P. Chavoshnejad, L. Chen, X. Yu, J. Hou, N. Filla, D. Zhu, T. Liu, G. Li, M.J. Razavi, X. Wang. "An integrated finite element method and machine learning algorithm for brain morphology prediction." Cerebral Cortex (2023): bhad208. https://academic.oup.com/cercor/article-abstract/33/15/9354/7191714

-

A. H. Foroughi, C. Valeri, D. Jiang, F. Ning, M. Razavi, M.J. Razavi. "Understanding compressive viscoelastic properties of additively manufactured PLA for bone-mimetic scaffold design." Medical Engineering & Physics 114 (2023): 103972. https://www.sciencedirect.com/science/article/abs/pii/S1350453323000243

- A. H. Foroughi, M. J. Razavi, "Multiobjective Shape Optimization of Bone Scaffolds: Enhancement of Mechanical Properties and Permeability", 2022, Acta Biomaterialia. https://doi.org/10.1016/j.actbio.2022.04.051

- A. H. Foroughi, M. J. Razavi, "Shape optimization of orthopedic porous scaffolds to enhance mechanical performance.", 2022, Journal of the Mechanical Behavior of Biomedical Materials, https://doi.org/10.1016/j.jmbbm.2022.105098

- M. K. Razavi Aghjeh, M. J. Razavi, "Effect of interfibre bonding on mechanical behaviour of electrospun fibrous mats'', 2022, In Mechanics of Fibrous Networks (pp. 317-354). Elsevier. https://doi.org/10.1016/B978-0-12-822207-2.00007-6

- P. Chavoshnejad, G. German, M.J. Razavi, "Hyperelastic Material Properties of Axonal fibers in Brain White Matter", 2021, Brain Multiphysics, https://doi.org/10.1016/j.brain.2021.100035.

- P. Chavoshnejad, A. H.Foroughi, N. Dhandapani, G. German, M.J. Razavi, " Effect of collagen degradation on the mechanical behavior and wrinkling of skin", 2021, Physical Review Letters E, https://doi.org/10.1103/PhysRevE.104.034406.

- N. Liu, P. Chavoshnejad, S. Li, M.J. Razavi, T. Liu, R. Pidaparti, X. Wang, "Geometrical nonlinear elasticity of axon under tension: A coarse-grained computational study", 2021, Biophysical Journal, https://doi.org/10.1016/j.bpj.2021.07.019

-

M.J.Razavi, T.Liu, X. Wang, "Mechanism Exploration of 3-Hinge Gyral Formation and Pattern Recognition'', 2021, Cerebral Cortex Communications, https://doi.org/10.1093/texcom/tgab044

-

P. Chavoshnejad, X. Li, S. Zhang, W. Dai, L. Vasung, T. Liu, T. Zhang, X. Wang, M.J.Razavi," Role of Axonal Fibers in the Cortical Folding Patterns: A Tale of Variability and Regularity", 2021, Brain Multiphysics, https://doi.org/10.1016/j.brain.2021.100029

- P. Chavoshnejad, O. Alsmairat, C. Ke, M.J.Razavi, "Effect of interfiber bonding on the rupture of electrospun fibrous mats'', 2020, Journal of Physics D: Applied Physics, https://doi.org/10.1088/1361-6463/abba95

- M. Brown, M. Mendoza, P. Chavoshnejad, M. J. Razavi, G. Mahler, A. Koh, “Electronic‐ECM: A Permeable Microporous Elastomer for an Advanced Bio‐Integrated Continuous Sensing Platform”, 2020, ADVANCED MATERIAL TECHNOLOGIES, https://doi.org/10.1002/admt.202000242.

- P. Chavoshnejad, M. J. Razavi, “Effect of the Interfiber Bonding on the Mechanical Behavior of Electrospun Fibrous Mats”, 2020, Scientific Reports 10 (7709 (2020)), https://doi.org/10.1038/s41598-020-64735.

- P. Chavoshnejad, S. More, M. J. Razavi, “From surface microrelief to big wrinkles in skin: A mechanical in-silico model”, Extreme Mechanics Letter, https://doi.org/10.1016/j.eml.2020.10064.

- N. A. Hossain, M. J. Razavi, S. Towfighian, “Analysis of mechanical deformation effect on the voltage generation of a vertical contact mode triboelectric generator”, Journal of Micromechanics and Microengineering, https://doi.org/10.1088/1361-6439/ab6c74.

- T. Zhang, H. Chen, M.J. Razavi, Y. Li, F. Ge, L. Gue, X. Wang, T. Liu, “Exploring 3-hinge gyral folding patterns among HCP Q3 868 human subjects”, 2018, Human Brain Mapping. https://doi.org/10.1002/hbm.24237

- F. Ge, X. Li, M.J. Razavi, H. Chen, T. Zhang, S. Zhang, L. Guo, X. Hu, X. Wang, T. Liu, “Denser Growing Fiber Connections Induce 3-hinge Gyral Folding”, 2017, https://doi.org/10.1093/cercor/bhx227

- M.J. Razavi, T. Zhang, H. Chen, S. Platt, Y. Zhao, L. Guo, X. Hu, X. Wang and T. Liu, “Radial Structure Scaffolds the Convolution Patterns of Developing Cerebral Cortex”, Frontiers in Computational Neuroscience, 2017, https://doi.org/10.3389/fncom.2017.00076

- M.J. Razavi, M. Reeves, X. Wang, “Mechanical role of a growing solid tumor on cortical folding”, Computer Methods in Biomechanics and Biomedical Engineering, 2017, 20(11), 1212-1222. https://doi.org/10.1080/10255842.2017.1340465

- K. Brooks, M.J. Razavi, X. Wang, J. Locklin, “The evolution of creased morphologies using reactive droplets in ultrathin films”, Advance Material Interface, 2017, https://doi.org/10.1002/admi.201700084

- X. Li, H. Chen, T. Zhang, X. Yu, X. Jiang, K. Li, L. Li, M.J. Razavi, X. Wang, X. Hu, J. Han, L. Guo, X. Hu, T. Liu, “Commonly preserved and species-specific gyral folding patterns across primate brains”, Brain Structure and Function, 2017, 222(5), 2127-2141. DOI: 10.1007/s00429-016-1329-3

- G. Stoychev, M.J. Razavi, X. Wang, L. Ionov, “4D origami by smart embroidery”, Macromolecular Rapid Communications, 2017, https://doi.org/10.1002/marc.201700213

- T. Zhang, M.J. Razavi, H. Chen, Y. Li, X. Li, L. Li, L. Guo, X. Hu, T. Liu, X. Wang, “Mechanisms of circumferential gyral convolution in primate brains”. Journal of Computational Neuroscience, 2017, 42, 217-229. https://doi.org/10.1007/s10827-017-0637-9

- T. Zhang, M.J. Razavi, X. Li, H. Chen, T. Liu, X. Wang, “Mechanism of Consistent Gyrus Formation: an Experimental and Computational Study”, Scientific Reports, 2016, 6 (37272). https://doi.org/10.1038/srep37272

- M.J. Razvavi, R. Pidaparti, X. Wang, “Surface and interfacial creases in a bilayer tubular soft tissue”, Physical Review E, 2016, 94 (022405). https://doi.org/10.1103/PhysRevE.94.022405

- K. Brooks, M.J. Razavi, X. Wang, J. Locklin, “Nanoscale Surface Creasing Induced by Post-Polymerization Modification”, ACS Nano, 2015, 5b04144. https://doi.org/10.1021/acsnano.5b04144

- M.J. Razavi, T. Zhang, T. Liu, X. Wang, “Cortical Folding Pattern and its Consistency Induced by Biological Growth”, Scientific Reports, 2015, 5, 14477. https://doi.org/10.1038/srep14477

- M.J. Razavi, T. Zhang, X. Li, T. Liu, X. Wang, “Role of mechanical factors in cortical folding development”, Physical Review E, 2015, 92 (3), 032701. https://doi.org/10.1103/PhysRevE.92.032701

- M.J. Razavi, X. Wang, “Morphological patterns of a growing biological tube in a confined environment with contacting boundary”, RSC Advances, 2015, 5 (10), 7440-7449. https://doi.org/10.1039/C4RA12795A

- T.N. Chakherlou, M.J. Razavi, A.B. Aghdam, B. Abazadeh,“An experimental investigation of the bolt clamping force and friction effect on the fatigue behaviour of aluminum alloy 2024-T3 double shear lap joint” , Materials & Design, 2011, 32 (8-9), 4641-4649. https://doi.org/10.1016/j.matdes.2011.04.022

- T.N. Chakherlou, M.J. Razavi, A.B. Aghdam,“ On the variation of clamping force in bolted double lap joints subjected to longitudinal loading: A numerical and experimental investigation”, Strain: An International Journal for Experimental Mechanics, 2012, 48 (1), 21-29. https://doi.org/10.1111/j.1475-1305.2010.00795.x

- T.N. Chakherlou, M.J. Razavi, B. Abazadeh,“Finite Element investigations of bolt clamping force and friction coefficient effect on the fatigue behaviour of aluminum alloy 2024-T3 in double shear lap joint”, Engineering Failure Analysis, 2013, 29, 62-74. https://doi.org/10.1016/j.engfailanal.2012.11.004

- M.R. Khoshravan, A. Khalili, M.J.Razavi, “Numerical Analysis of the Effect of Added hole on the Stress Concentration of a Perforated Plate and Determining of Its Optimum Location”, Key Engineering Materials, Vols. 452-453, Advances in Fracture and Damage Mechanics IX, 2011, 793-796. https://doi.org/10.4028/www.scientific.net/KEM.452-453.793

Research positions

We invite applications for PhD graduate fellowship positions and visiting scholar positions. The preferred areas of interest are in solid mechanics. Qualified candidates are expected to have a master's degree (preferred) or bachelor's degree in mechanical engineering, engineering mechanics, physics or related disciplines. Experience with modeling and simulation based on finite element model is essential. Please send your CV to Professor Razavi.

Many research topics are available for current master's and bachelor's students at Binghamton University. The projects are related to analytical and computational study of mechanics of soft biological tissues and mechanical behavior of solid structures. Please send your CV and interested research area to Professor Razavi to have more discussion.