The Hyperloop hype

The Binghamton Hyperloop team wants to stand out from the competition this year and the team members are using their imagination to make that happen.

The history of the world is the history of transportation. The invention of the first sailboat, the railroad, the automobile and airplanes have all fundamentally changed how we interact, what we have access to and how much of the world we can experience.

Transportation defines society.

So, what can we expect next in the world of transportation?

The past few years, we have seen progress on self-driving vehicles but there have also been crashes and fears associated with the loss of control.

The sci-fi dream of teleportation is still – at least currently – just a dream.

Students at Binghamton University have been developing their own version of what could be the real future of human transportation, the Hyperloop pod.

Hyperloop is a proposed human transport system in which passengers ride in cars called pods — similar to the pneumatic tubes at a bank drive-through — at, theoretically, up to 750 miles per hour. It was first proposed in 2012 by SpaceX Founder and CEO Elon Musk.

The Binghamton Hyperloop team, now in its third year, is taking the lessons from years one and two to heart.

“The first year, the team was so new and trying to really get a handle on things,” explained senior industrial and systems engineering major Kasey Hill, who is a project manager for the team. “Last year’s team made it all the way to the SpaceX competition in California, so now we know what to expect and are working harder than ever to really advance our pod.”

The 2016-2017 Binghamton Hyperloop team competed last summer alongside pods from the University of Washington, Arizona State University, Purdue University and the Technical University of Munich, which won the competition.

The Binghamton team was one of only 24 finalists selected for the competition from more than a thousand applicants.

Taking Binghamton Hyperloop to the next level

Improving on last year’s success is a difficult task, but this year’s team is up to the challenge.

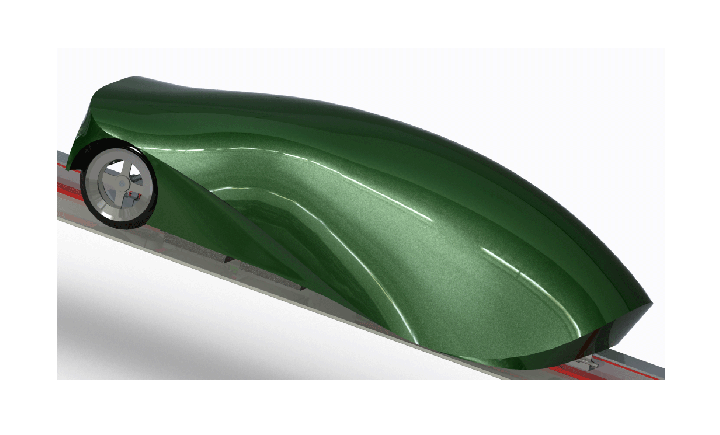

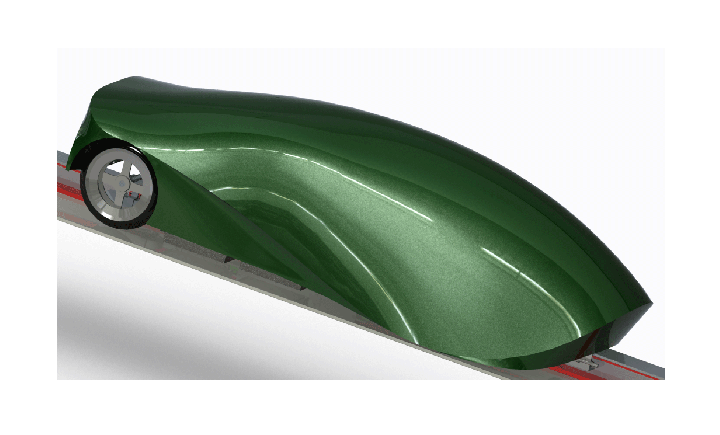

The brakes, the battery and the shell of the pod have all been altered this year, but one major change is the addition of a levitation system.

Senior electrical engineering major Anthony Dorsa worked on the electrical system in last year’s Hyperloop pod and is in charge of this year’s levitation system.

“We wanted to really stand out. Last year’s winning team used wheels and we figured most teams would try to copy that strategy, so we went with a levitation system instead,” explained Dorsa. “Plus, it’s more in the spirit of what a real Hyperloop pod would do. Wheels would just burn out at those high speeds, so they aren’t practical.”

The levitation system uses magnets to keep the pod from creating extra resistance against the track when it reaches top speeds.

Connor Wickham and Boxu Zhu are both senior mechanical engineering majors who have been working on a variety of projects for the Hyperloop pod, including the braking system and the overall design.

Since the Hyperloop team will be entering the speed competition, members focused on ways to decrease the drag coefficient of the pod – a dimensionless quantity used to explain the resistance an object faces.

“Based on our calculations, our design will have a drag coefficient of .09. For something box-shaped like a Jeep, the drag coefficient is .4 or an average car is usually closer to .22,” explained Zhu.

The low drag coefficient combined with the levitation system will help the Hyperloop pod reach higher speeds with less resistance.

While the levitation system and the unique design are novel for most, the braking system uses the all-too-familiar brake pad.

“We actually went to a local auto shop just to see if the brake pads they had would work,” said Wickham. “When the guy working there asked what type of car we had, we weren’t quite sure how to answer and probably just confused everyone there. But he ended up giving us a few tips and helped us figure out how to get what we needed. Now, our pod uses brake pads that are similar to what race cars use.”

Pod racing on a budget

One big concern for this year’s team is getting enough funds to build the Hyperloop pod and to travel to California if the pod makes it to this year’s SpaceX competition.

“We’re competing against some really big schools,” said Hill. “We might not be able to out-money them, but what we can do is out-dream them.”

Compared to other Hyperloop teams, the Binghamton Hyperloop pod has always been considerably cheaper to produce.

Darren Silvanic, a senior industrial and systems engineering major and team lead, explained that “most of the pods at last year’s competition cost anywhere between $50k and $150k to build. Our proposed design would only cost about $25K, but we are going to need a lot of assistance to meet that goal. We are thankful for Avangrid, which has been generous enough to give us an initial budget, but are actively looking for donations and sponsors to help fund the rest.”

The team has received support from the greater Binghamton community in the past and is again in need of sponsorship for this year’s Hyperloop pod. Donations are being accepted through the Thomas J. Watson School of Engineering and Applied Science website. Industry and corporate sponsors looking to work with the Hyperloop team can email the team for more information at buhyperloop@gmail.com.

The 2017-2018 group started work soon after last year’s competition ended. The design proposal and data analysis package were delivered to SpaceX in mid-January and now the students are waiting to hear if they qualify for this year’s competition.

They will find out in March if they qualify, but will continue to build their Hyperloop pod regardless to get the experience and practice that the project provides.