Projects

-

Towards Smart Micro-Bio-Nano Factory: Automated Nano/Micro Manipulation under External Common Fields

One of the fundamental challenges in micro- and nano-robotics is to develop automated systems that are capable of precisely and reliably manipulating a large number of objects simultaneously. Parallel manipulation capabilities will address assembly and production challenges associated with handling massive numbers of miniaturized components and lead to the realization of smart micro-bio-nano factories. In such systems, micro- and nano-scale components of varying shapes and materials can be assembled together to create functional micro/nano devices or biological structures. While a number of micro and nano manipulation techniques have been introduced over the past couple of decades, automation has been mostly restricted to moving a limited number of components in small workspace volumes with severe constraints along the vertical direction. This research aims to develop control and planning methods to overcome this automation barrier and realize automated and precise manipulation, efficient and reliable assembly and scalable manufacturing of massive and heterogeneous micro/nano components into functional devices in three dimensions.

1. Motion Control and Manipulation of Nanowires under Electric-Fields in Fluid Suspension

The automated sorting and positioning of nanowires and nanotubes is essential to enabling the scalable manufacturing of nanodevices for a variety of applications, including nanoelectronics and biological applications. However, two fundamental challenges still remain: (i) automated placement of individual nanostructures in precise locations and (ii) the characterization and sorting of highly variable nanomaterials to construct well-controlled nanodevices. Overcoming these challenges could enable further potential capacities of assembling and manufacturing functional nanodevices.

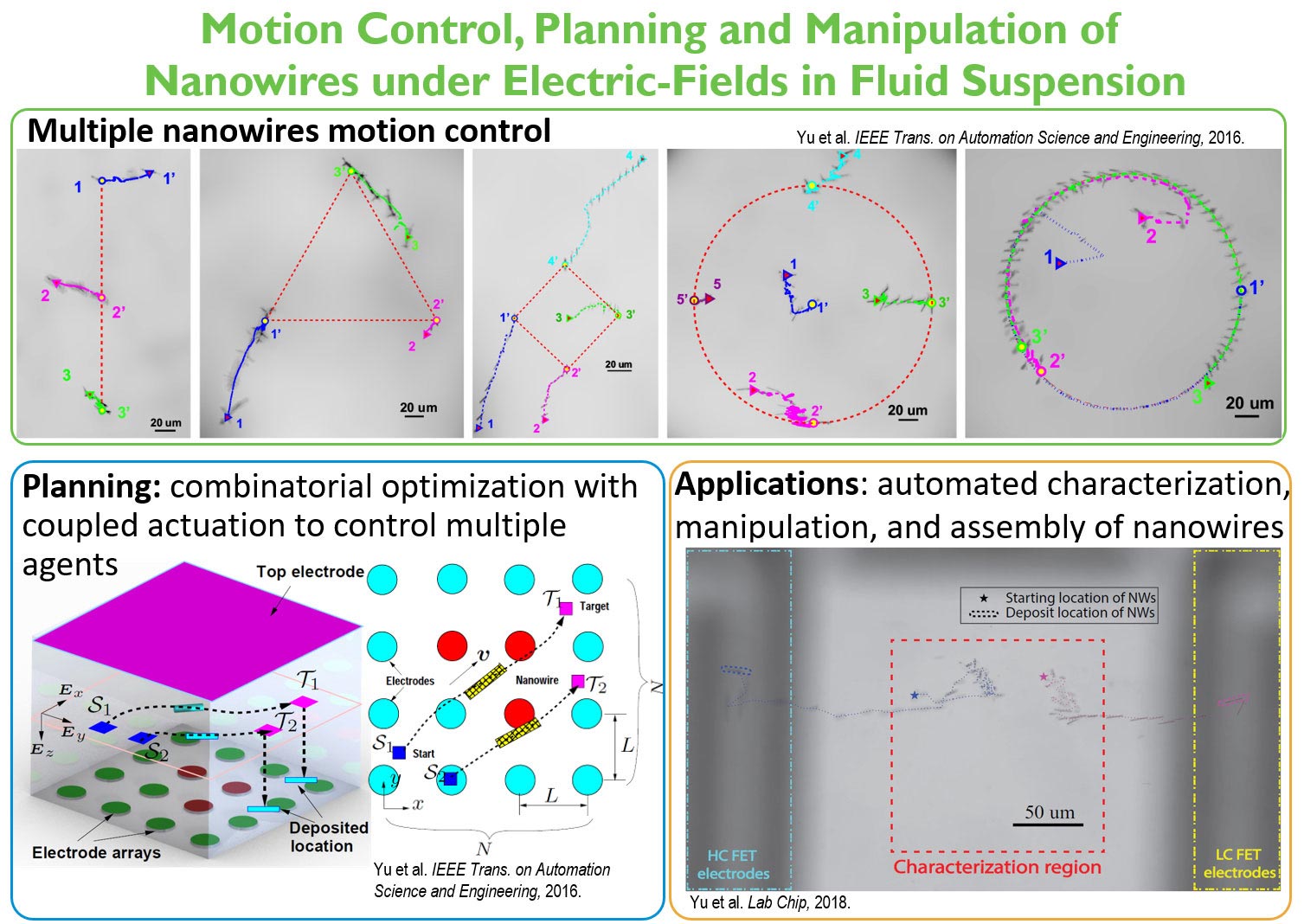

In this project, we developed an electric-field-based method for motion control and manipulation of nanowires in liquid suspension with a simple, generic set of electrodes. A simplified dynamic model with vision-feedback is used to control the nanowire motion in dilute suspension with a set of controllable electrodes.

2. Real-time Motion Planning of Multiple Nanowires in Fluid Suspension under Electric-Field Actuation

The ability to efficiently manipulate massive number of nano- and micro-scale objects is a key step in enabling smart micro/nano-device assembly. In this project, we propose and demonstrate real-time motion-planning algorithms for effectively steering multiple nanowires simultaneously in fluid suspension using electric fields. Heuristic-, network flow-, sampling- and supervised learning based motion planning algorithms are utilized to achieve the effective and efficient nanowires manipulation.

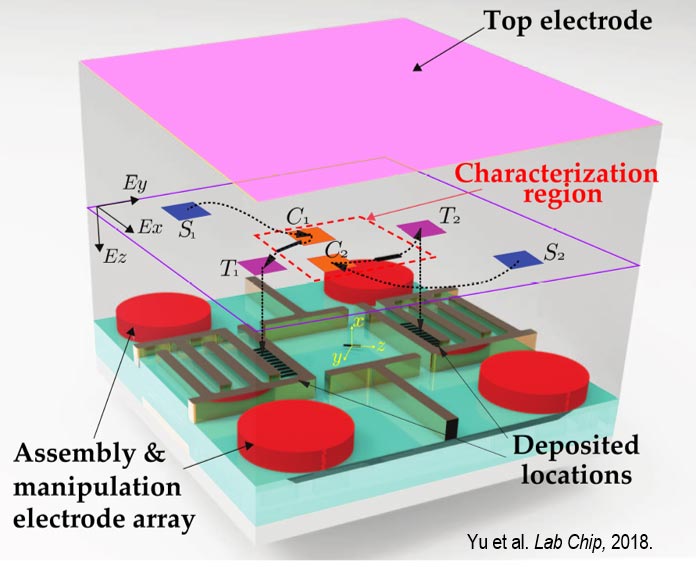

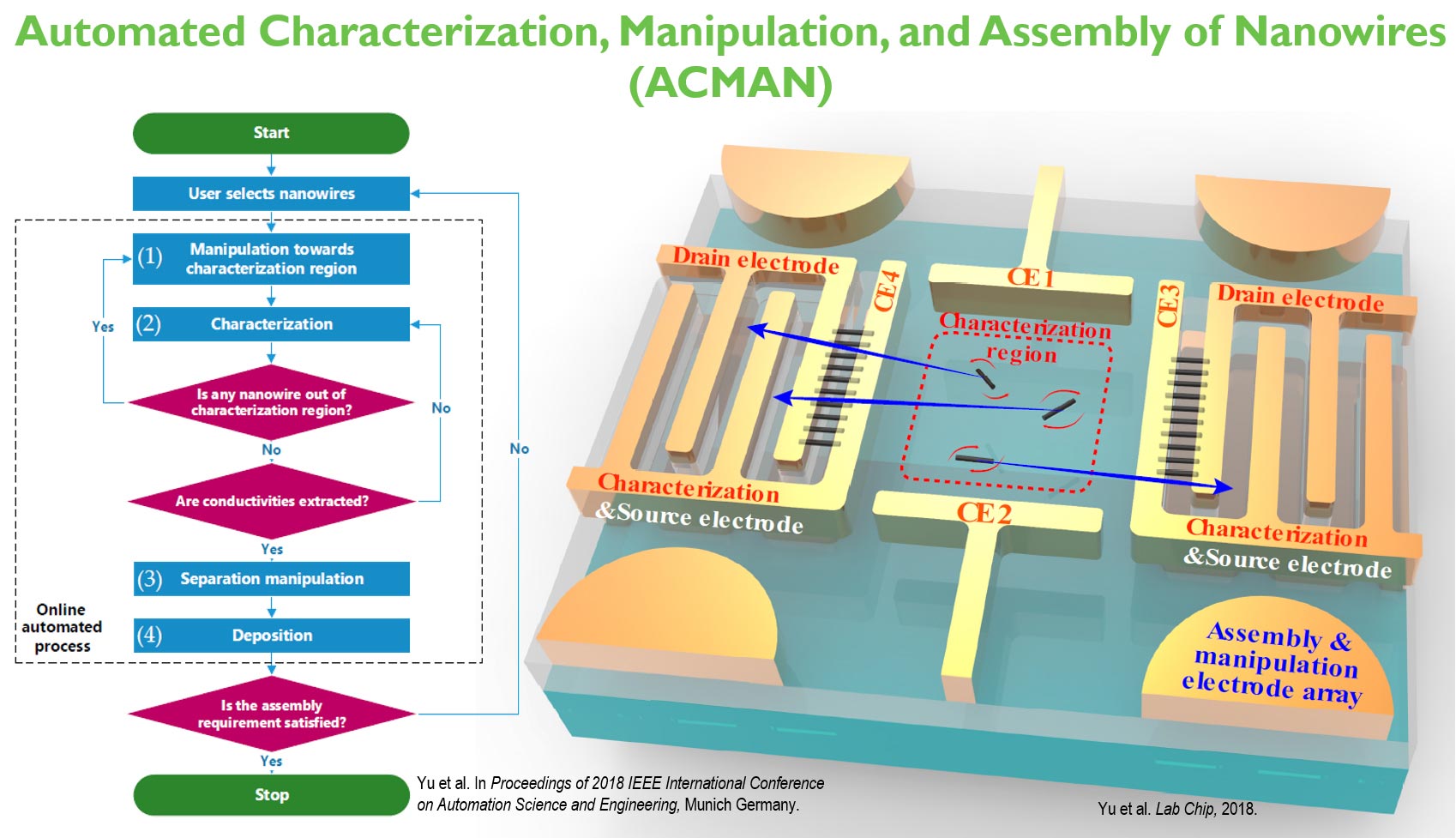

3. Automated Characterization, Manipulation and Assembly of Nanowires for Device Fabrication

In this project, we propose and demonstrate an integrated, electric-field based method for the simultaneous automated characterization, manipulation and assembly of nanowires (ACMAN) with selectable electrical conductivities into nanodevices. We combine contactless and solution-based electro-orientation spectroscopy and electrophoresis-based motion-control, planning and manipulation strategies to simultaneously characterize and manipulate multiple individual nanowires. These nanowires can be selected according to their electrical characteristics and precisely positioned at different locations in a low-conductivity liquid to form functional nanodevices with desired electrical properties. We validate the ACMAN design by assembling field-effect transistors (FETs) with silicon nanowires of selected electrical conductivities. The design scheme provides a key enabling technology for the scalable, automated sorting and assembly of nanowires and nanotubes to build functional nanodevices.

National Science Foundation, CMMI-2146056, PI, 3/1/2022-2/28/2027

The research objectives are to (1) design an adaptive robust ensemble control for great quantities of agents in a complex three-dimensional microfluidic environment under common electric fields; (2) analyze the controllability and manipulability of the system to identify the most effective electrode pattern and plan efficient trajectories of individual objects; and (3) investigate control schemes that enable functional nanodevice assembly with applications to next-generation neuromorphic computing. In the long term, this research will support engineering tools for automated microscale and nanoscale bio-factories through the manipulation of large volumes of objects, which will have significant impacts on target-oriented drug delivery and precision medicine engineering.

-

Ray-FL-FDA: Ray-Empowered Federated Learning of Functional Data Analysis

SUNY-IBM AI Research Alliance, PI, 6/1/2024-12/1/2025

This project leverages the prior development of Ray-F2R and Ray-F2R-FL and develops the broadly-applicable computing platform, Ray-empowered Federated Learning of Functional Data Analysis (Ray-FL-FDA). The newly proposed Ray-FL-FDA aims to develop a privacy-preserving, robust, and scalable FL framework for FDA.

-

Hybrid Memristive Neural Network for Neuromorphic Computing with Automated Manipulation of Nanoparticles

SUNY Multidisciplinary Team Seed Grant, PI, 10/15/2020-12/31/2023

This project aims to create a novel hybrid memristive neural network (MNN) structure that combines precisely controlled neuromorphic nanowire networks and Resistive Random Access Memory components. The proposed hybrid MNNs exhibit emergent brain-like complexity properties, including nonlinear stochastic dynamics and memorization, making them a unique experimental system for emulating intelligence.

-

Automated Integration with Micro/Nanowirebased Fine-Pitch Interconnects for 3D Packaging

Integrated Electronics Engineering Center (IEEC) Pooled Project, PI, 8/1/2020-8/30/2021

This project aims to create novel micro or nanowire-based fine-pitch interconnects for 3D packaging using precisely controlled micro or nanowires. An automated, precise 3D manipulation scheme is proposed to assemble multiple micro and nanowires in fluid suspension under electrical field. A solution-based approach is designed fabricating interconnects using vertically aligned and horizontally patterned micro or nanowires. This project addresses important challenges regarding the precise and scalable assembly for high density interconnects in 3D packaging.

-

Cooperative Control and Motion Planning of Multiple Autonomous Vehicles/Robots with Aggressive Maneuvers.

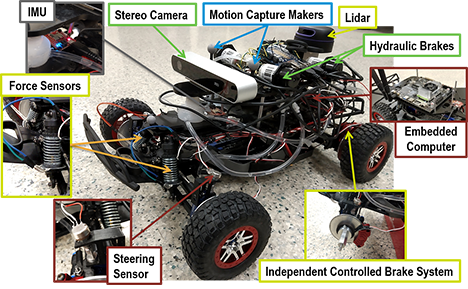

To reinforce autonomous driving with multiple robots/vehicles, handling the unstable robot or vehicle motion, such as high-speed obstacle avoidance and motion planning with aggressive and agile maneuvers, is crucial for safety-preserved agile vehicles. Extremely skilled human drivers demonstrate superior capability to conduct seemingly unstable yet safe maneuvers. These extremely agile human driving skills motivate the work on handling unstable vehicles. In this work, we propose to develop network-based control systems for a group of agile vehicles for safety-preserved and efficient autonomous driving.

-

Complete and Optimal Control and Planning of Road Maintenance and Rehabilitation Robot Systems

The U.S. government has spent $79 billion on road maintenance in 2016. Approximately $134 million has been spent on pavement preventive maintenance in New York State in 2017, where more than 3,865 lane miles of pavement needed to be treated by crack sealing and filling. Efficient and simultaneous detection and recovery of cracks on ground surfaces can significantly reduce the cost and improve safety in road maintenance. This project aims to develop a complete and optimal control and planning scheme of multiple-robot system to automate the road maintenance and rehabilitation.

The research tasks include

1. Learning-based Safety-preserved Control and Planning for Robotic Systems

2. Field Robot Coverage Planning

3. Human, Environment and Multiple-robot Interactions

-

Universal Instruments/United Technologies Aerospace (UIC/UTAS) vibration project

Integrated Electronics Engineering Center, Binghamton University, 8/18/2020-9/3/2020

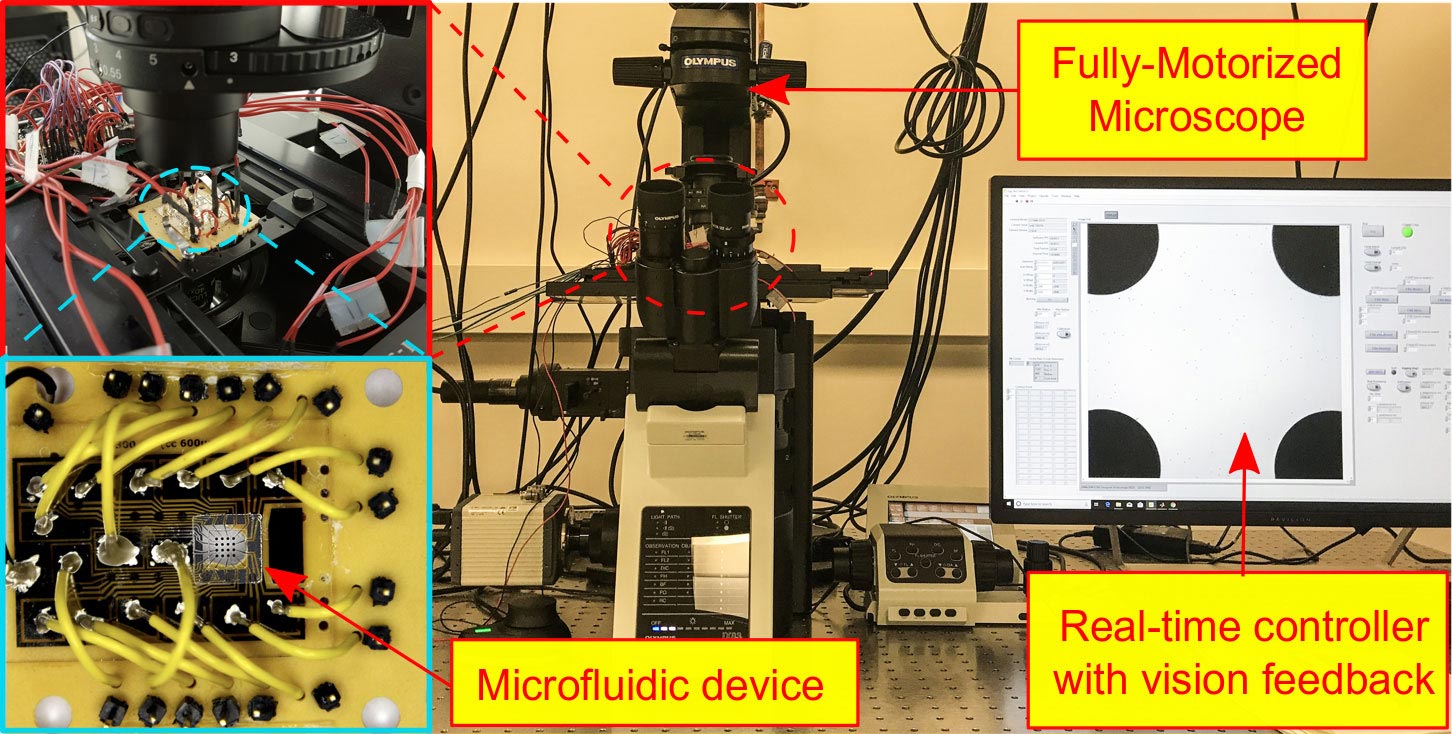

Facilities

- Automated Microscope System

- Fully-Motorized Research Inverted Microscope with Fluorescence and Phase Contrast (Olympus IX83)

- Scientific CMOS Camera

- LabVIEW Data Acquisition System

- Motion Capture System

Eight motion capture cameras with excellent precision (OptiTrack Flex 3) - Other Equipment The Watson School of Engineering and Applied Science at Binghamton University is equipped with state-of-the-art facilities.