MPM Momentum Screen Printer

MPM printer is a high-speed, high-precision systems for depositing precise patterns of solder paste on printed circuit boards through foil stencils.Solder Paste, a complex mixture of tiny particles of solder alloy and flux vehicle, is a challenging material to print onto a bare Surface Mount Technology (SMT) PCB. Solder paste printed deposits are essential to forming defect-free solder joints, the electrical and physical connections between electronic components and the PCB assembly.

Koh Young aSpire3 SPI

- aSpire3 is a world-best performance 3D Solder Paste Inspection.

- Industry-leading measurement accuracy and inspection reliability

- Full 3D data-based process optimization solution: Realization of industry 4.0 / Smart Factory

- Real-time process optimization through powerful SPC analytics

Ekra Screen Printer

- EKRA Serio 4000 printer is an economical inline system with a closed-loop print-head, stencil underside cleaning, the EKRA Vision Alignment System EVA and the iQUESS (quick exchange squeegee system).

- Alignment repeatability ± 12,5 μm @ 6 Sigma

- EVA TM – EKRA Vision Alignment System

- Cycle time: 11/9 s + print

- Print format up to 610 x 510 mm

- Suitable for stencils up to 31 inch

- Program changeover < 2 min

UIC Fuzion Mounter

- Fuzion is a SMT equipment that picks electronic components from feeders and place on PCBs.

- The FZ7 head quickly and accurately places components as small as 01005 up to 55mm square with single field-of-view inspection and up to 25mm tall.

- Precision accuracy (27micro-meter @Cpk>1)

- Place components up to 150mm with multiple fields of view.

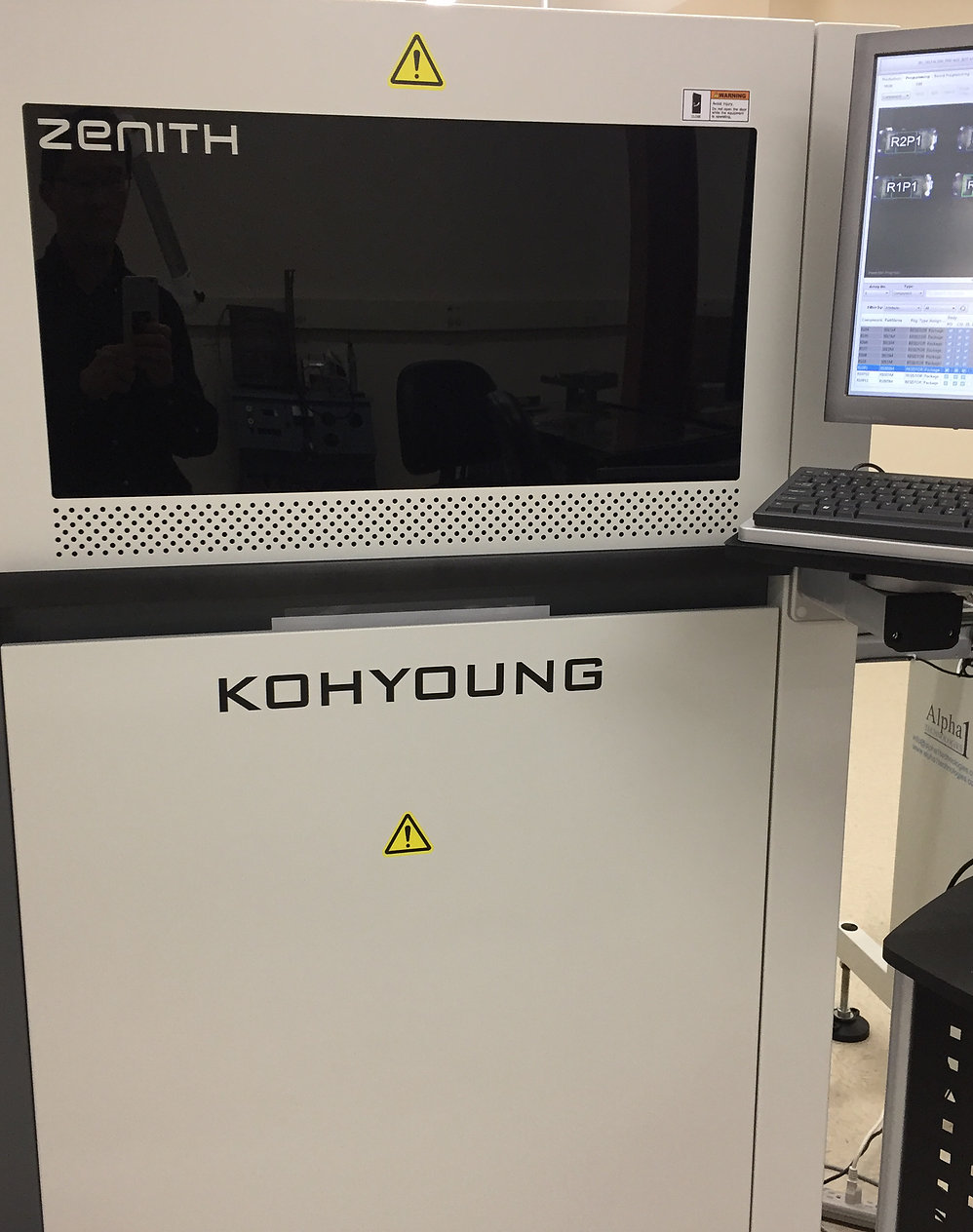

Koh Young Zenith PRE-AOI

- Zenith is the world's best-selling &first full 3D Automated Optical Inspection.

- Eliminates all the sources of defects using full 3D measuring inspection equipment skills.

- Full 3D data-based process optimization solution: Realization of industry 4.0 smart factory

Heller Reflow Oven

- Heller 1700 model supports high mix/medium volume throughput at speeds up to 24 inches per minutes.

- The most efficient heat transfer from extra high volume, high-velocity, heating modules, producing heater module response of less than one second to temperature changes of less than 0.1'C.

- Wide process window allows many different boards to be run on single temperature profile.

Thermal Warpage Inspection system

- Perform warpage inspection under reflow temperature or set temperature conditions, without the need for sample preparation such as bump removal nor paint treatment required by a general warpage inspection apparatus. Applicable work size is max. 100x100mm, and a high-speed convection heater capable of heating speed 3℃/sec is included.

- Heating temperatures range from -55℃ to 260℃ (Target)