Archaeologists recovered nearly 6,000 artifacts during the survey and site examination investigations. In addition to these artifacts which were removed from the site for analysis and curation at Binghamton University, crews also counted, weighed, and discarded in the field materials related to blacksmithing including coal, charcoal, and slag. Brick is not typically curated by PAF, so these were measured and discarded, as well. Almost 60% of the artifacts in the analyzed assemblage could be directly related to blacksmithing activities, including fragment of stock metal (the base material used by smiths), tools, wagon parts, and horseshoe nails. Most of the other artifacts consisted of architectural debris like nails and window glass, with small percentages of smoking pipes, food-related artifacts (like ceramic dishes), and animal bones. The latter indicate that meals (probably lunch) were taken at the shop, the dishes and bottles may have been used for eating or could have been re-purposed as containers for flux, chemicals, or other materials related to the shop's function.

The most numerous blacksmithing artifact type recovered was undiagnostic metal (n=2,048, 59%). These fragments ranged from unrecognizable rusted bits of metal to pieces of identified tools. Blacksmiths often experimented with extra material on hand to fashion functional pieces of equipment, though not always with great success (Gibb 1985).

Horseshoe nails, fragments, and tips were the next most numerous artifact type (n=1,123, 32.2%). Horseshoeing constituted one of the blacksmith's essential functions in society (Gibb 1985; Richardson 1889; Watson 1968). Three complete horseshoe nails, 716 horseshoe nail fragments, and 404 horseshoe nail tips were recovered, indicating that horseshoeing was regularly conducted at this site (Rudler et al. 2006; Watson 1968).

Excavations encountered stock metal across the entire site. Blacksmiths bought much of the raw metal they used as bar stock. It was sold as flat, round, oval, or square stock in various sizes and lengths. Sections of stock were cut off by the blacksmith as needed, until all that remained was a roughly 1 inch piece. Finding fragments of stock this size is common in blacksmith shops, as this is about the smallest piece that can be handled with a pair of blacksmith's tongs (Gibb 1985). Bar stock fragments were often tossed on the floor near the forge or in the nearest scrap pile. Flat stock was most numerous (n=117), with smaller amounts of square (n=31), round (n=17), and oval stock (n=3) fragments. Lengths of flat stock with thicknesses suitable for wagon tires were found in Unit 1 (n=4), Unit 2 (n=1), and Unit 5 (n=8). Flat stock with thickness suitable for barrel straps was recovered from Unit 2 (n=7) and Unit 4 (n=1). Unit 1 contained round stock (n=2) that appeared to have been used for making bolts. The remainder of the metal stock could have been used for a variety of purposes.

Excavations revealed 31 bolts and most were hand forged. Two methods were used to make these bolts. The first is by using a bolt header: a bolt blank is fitted with a ring at the top, is heated, and then the heading tool is struck on top to forge-weld it together. The second method involves taking a bolt blank, and welding it into a piece of squared off flat stock with a hole drilled into it. The latter appears to be the predominant method used at the Chittenango Blacksmith Shop site, as most of the wrought bolts appear to have this construction. However, two heading tools were recovered from the site, indicating that both methods were used.

Crews also recovered evidence of the wagon-making business. Eighteen wagon or carriage parts were recovered from the site, of which 15 were tire bolts. Tire bolts are distinctive, recessed-headed bolts designed to hold the metal tire onto the wooden fellows of a wagon wheel. Nine of the bolts were cut, indicating that the metal tire had been removed from the wooden supports, but the remaining six bolts were complete, suggesting the wheel remained assembled. These intact bolts likely originated in the wagon shop's scrap pile. Other wagon/carriage parts recovered include a fellow plate, a ferrule, and an axle clip.

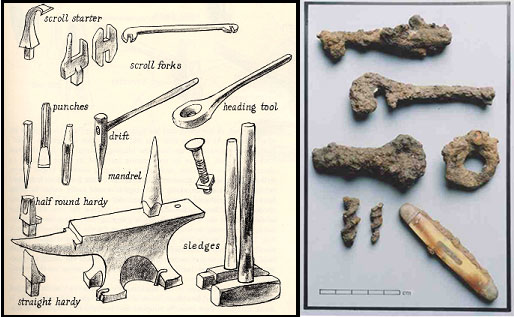

Archaeologists found four other blacksmithing tools in addition to the two heading tools mentioned above. The other tools were drill bit fragments, a punch, and a scroll fork/wrench. The drill bits were not hand wrought and were broken, possibly from attempting to penetrate metal. The punch was also used to cut holes in metal. This example was apparently made from a tapered segment of round stock metal. The scroll fork or wrench is a small twisting tool that could have been used to add decorative touches to hand forged products. The figures below show the tools we found at the site and what they would have looked like before they rusted in the ground.